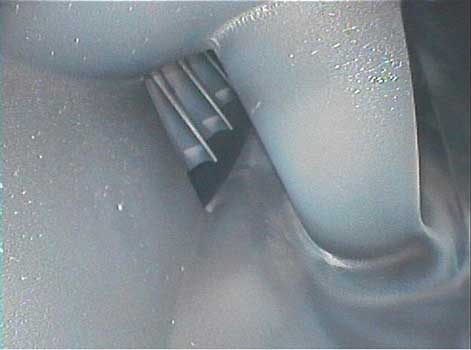

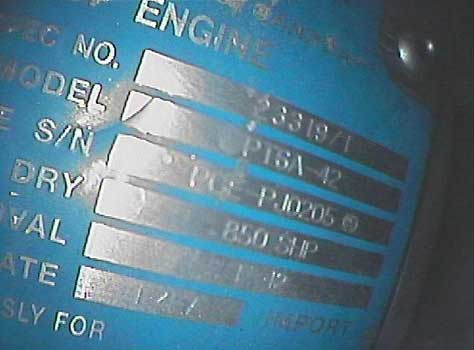

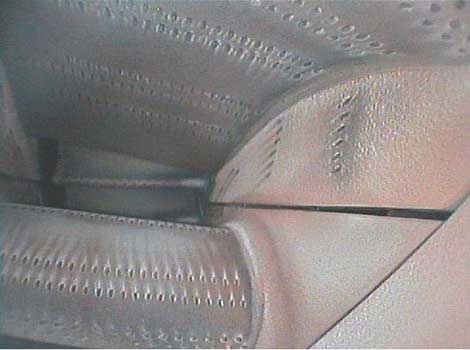

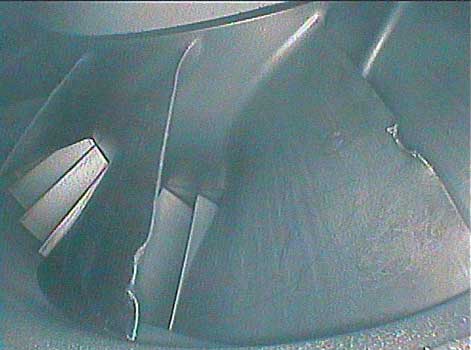

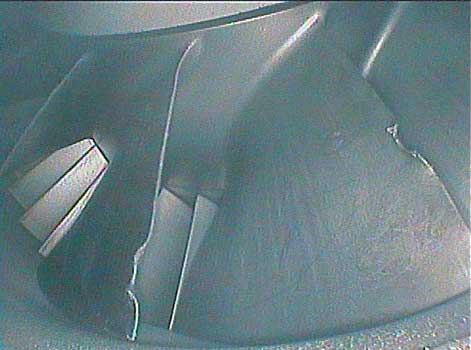

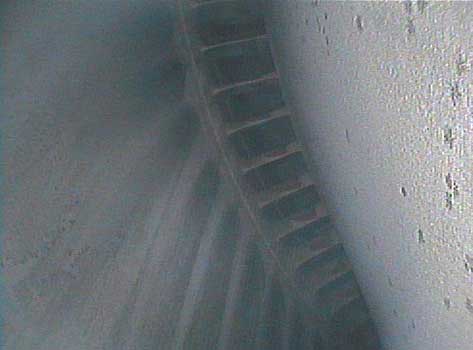

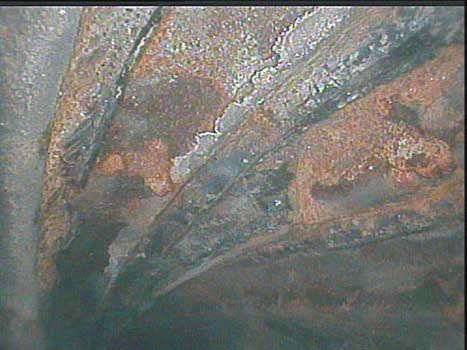

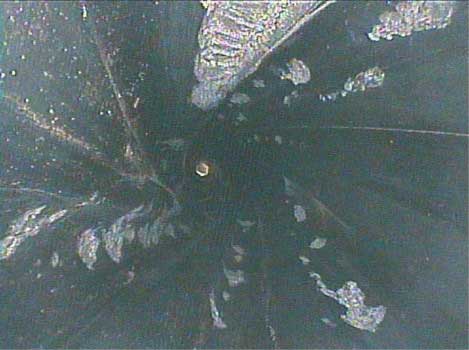

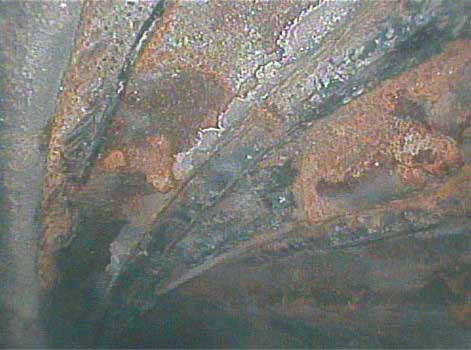

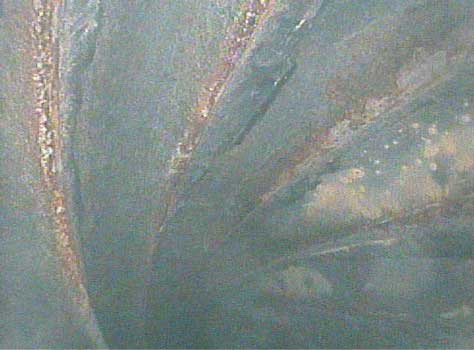

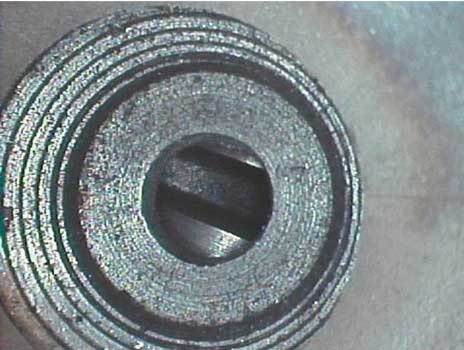

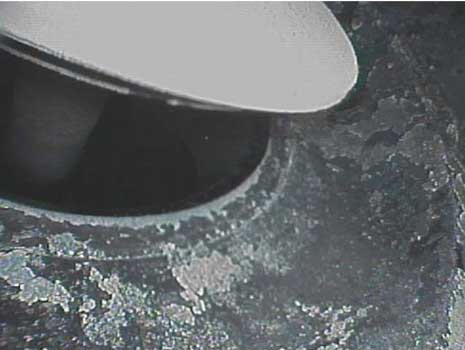

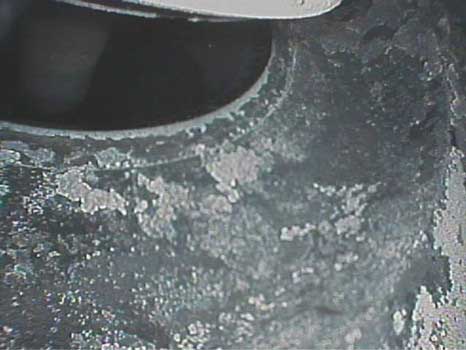

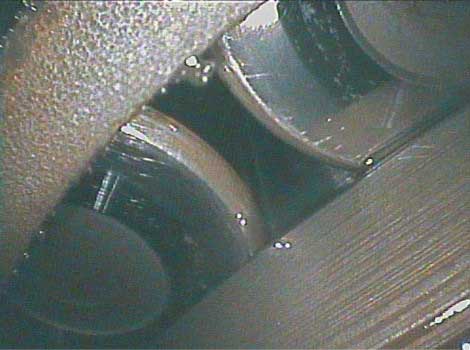

A Calgary, Canada based oil field service company that provides drilling fluid conditioning as well as drilling waste mitigation services to clients in North America and Canada purchased the 6.9mm x 1.5m VJ-Advance (VJ-ADV) articulating video borescope for their bearings, pulleys and rollers. Preventative maintenance is important to ensure that equipment is working at maximum efficiency over long periods of time. Maintenance on conveyors can be difficult and dangerous but the VJ-ADV has been a great addition to the toolbox. All inspections and adjustments of bearings, pulleys and rollers can be made from outside the conveyor without having to take the system apart.