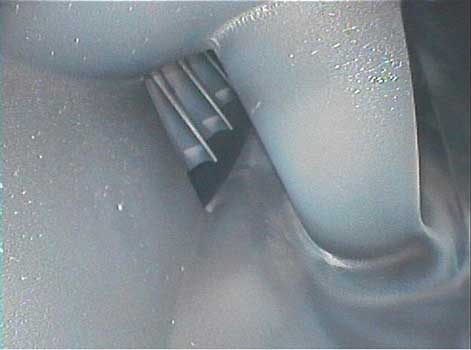

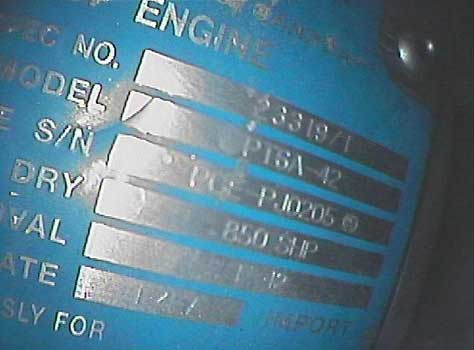

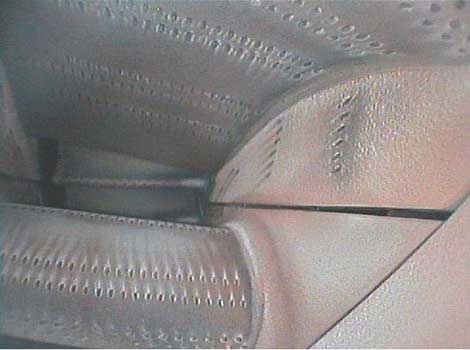

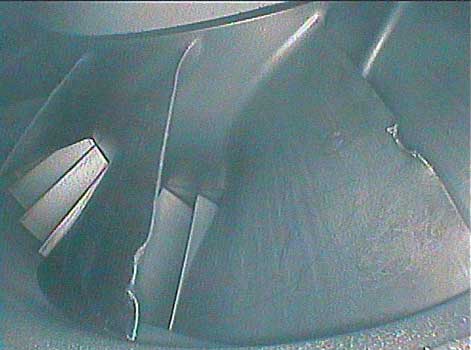

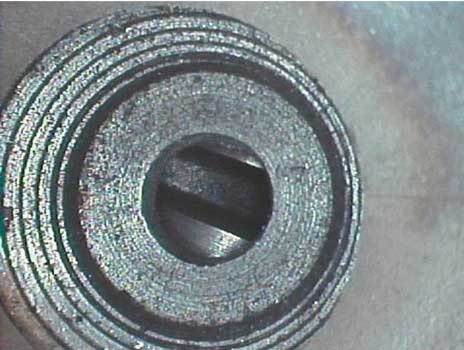

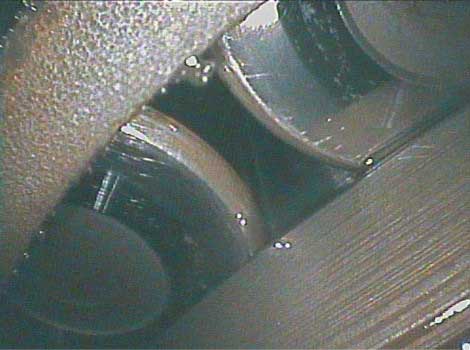

A plywood manufacturer needed to inspect the roller bearings for its main conveyor motors. This inspection required a shutdown of the entire production line, and every minute of downtime would cost money. Additionally, because the motors were located in hard to reach areas, some several meters high, a portable and lightweight instrument would be needed.

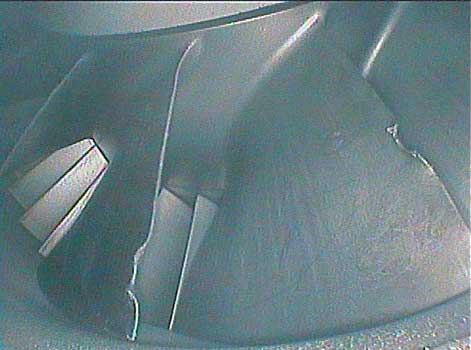

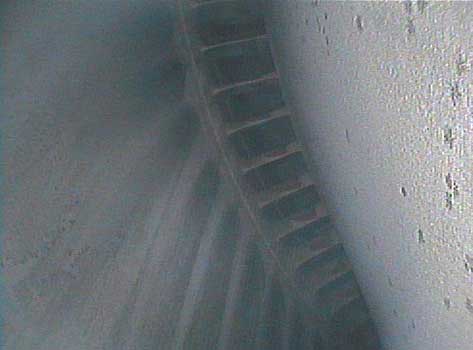

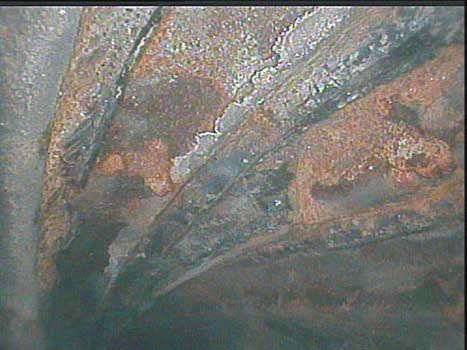

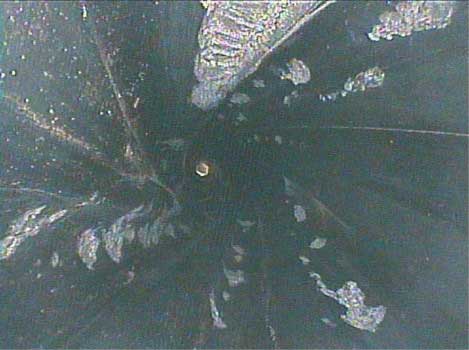

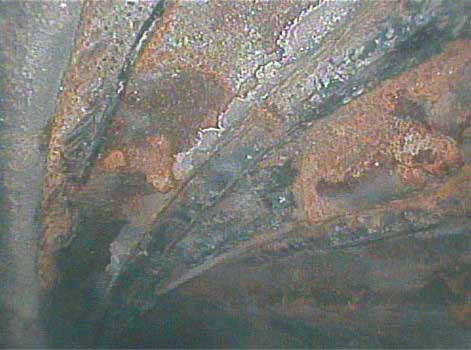

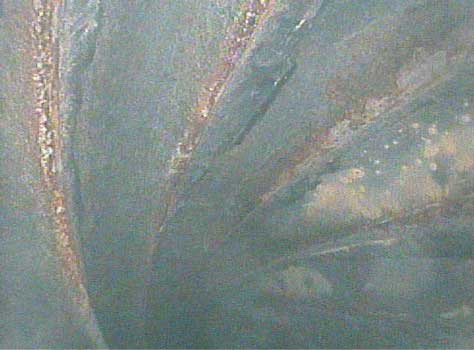

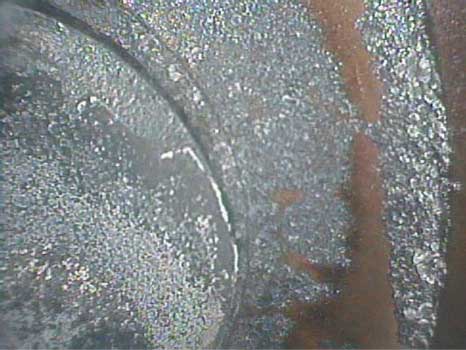

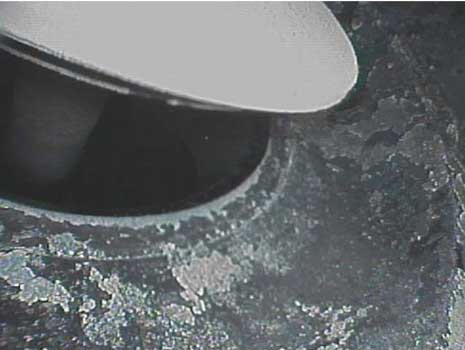

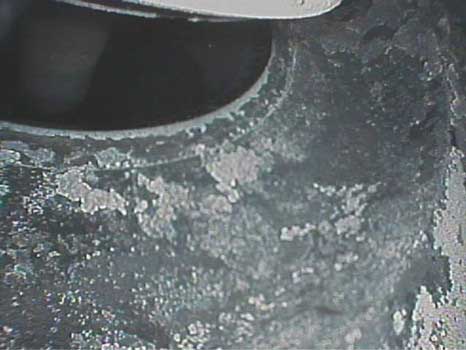

The VJ-ADV video borescope from RF System Lab was not only able to verify the condition of the roller bearings in record time, technicians used the onboard image capture capability of the VJ-ADV to document and archive pictures for future reference.

Weighing only 22 oz., the VJ-ADV video borescope was by far the lightest instrument ever used for these inspections. Additionally, the one-handed operation afforded by the design of the scope provided an extra measure of convenience and safety for the technician.