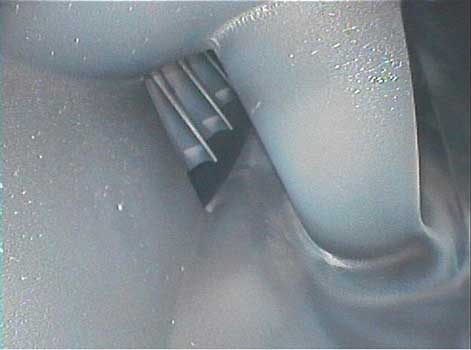

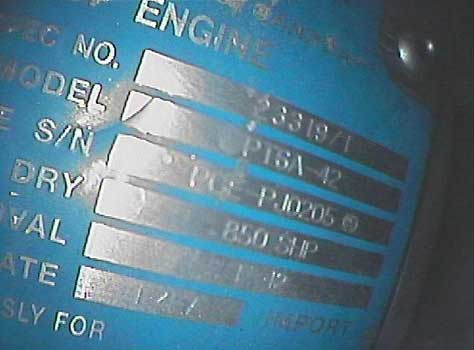

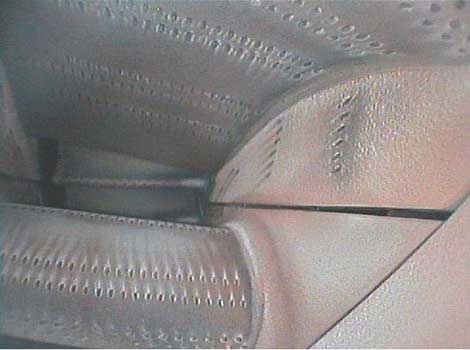

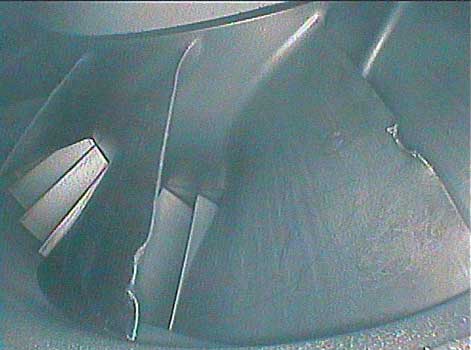

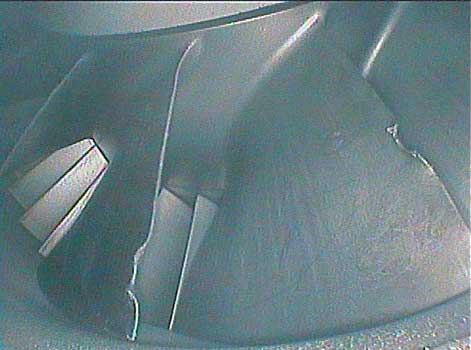

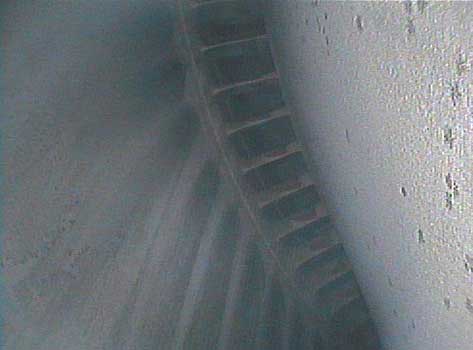

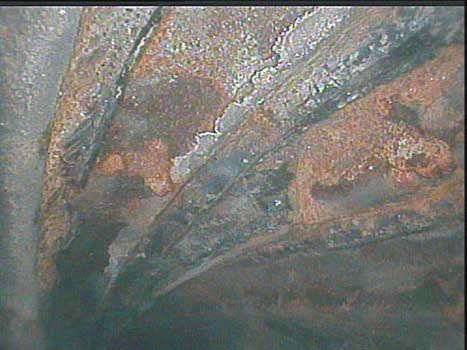

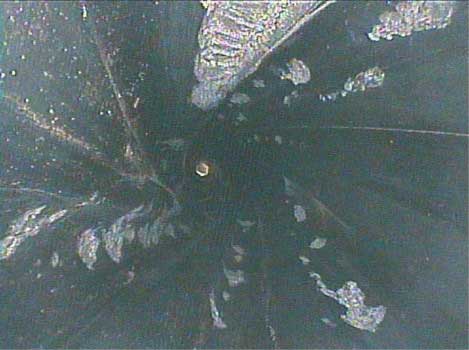

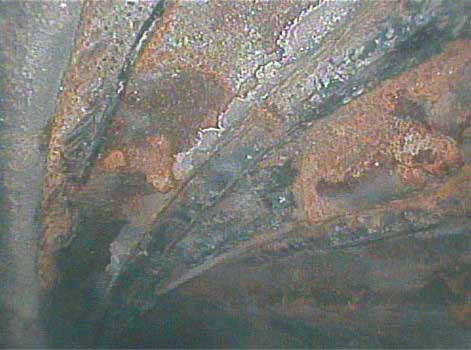

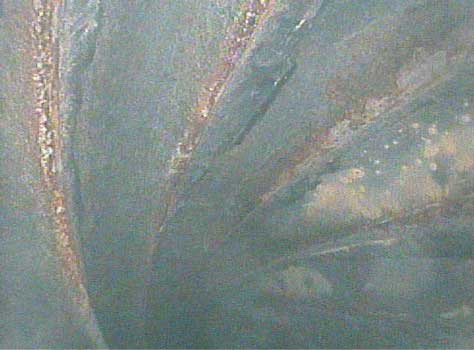

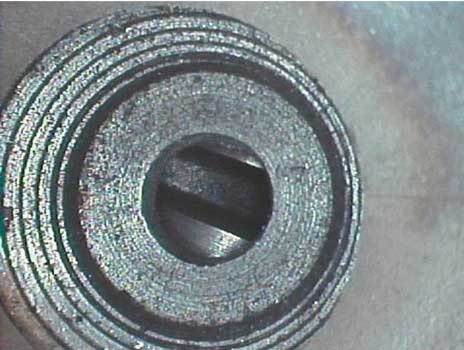

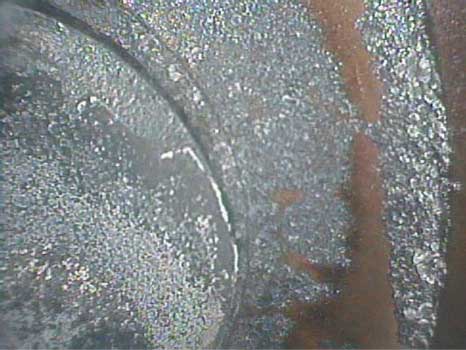

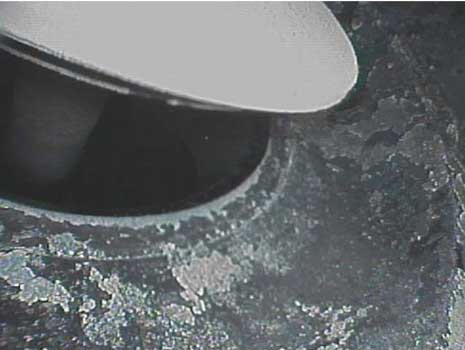

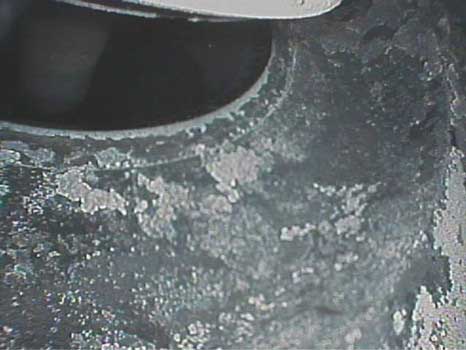

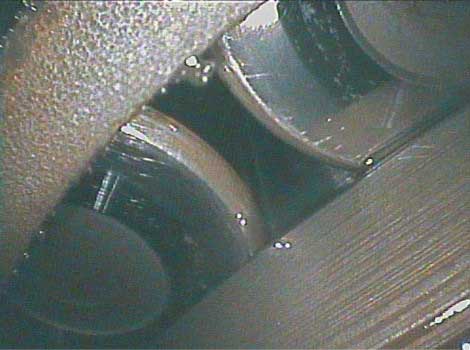

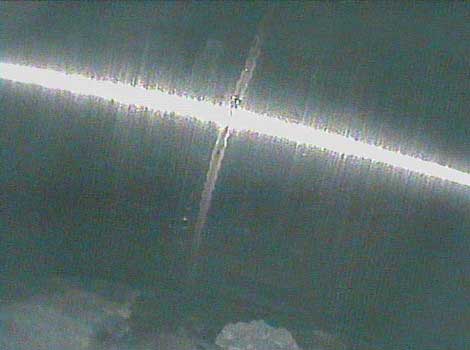

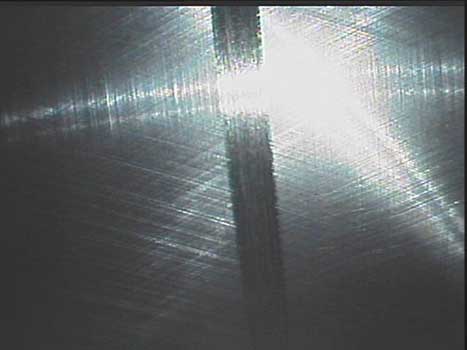

A worldwide leading supplier of high-tech polymer materials has added the VJ-Advance articulating video borescope to their toolbox for a variety of remote visual inspections. They’ve found the 6.9mm x 3.0m to be an essential tool in their manufacturing plant especially for the extruder barrel. A typical single screw extruder has four major components: gearbox, feed throat, barrel and feedscrew.

One of the main factors in achieving optimum efficiency is maintaining the proper alignment of the rotational center of the screw to the rotational center of the gearbox thrust shaft. The extruder barrel plays a huge part in this manufacturing plant. The VJ-Advance articulating video borescope saves time and money by allowing maintenance technicians to prevent downtime and avoid high costs of component replacement.