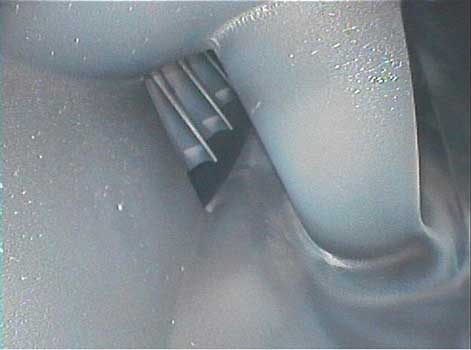

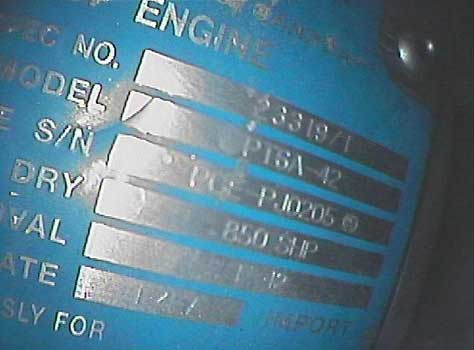

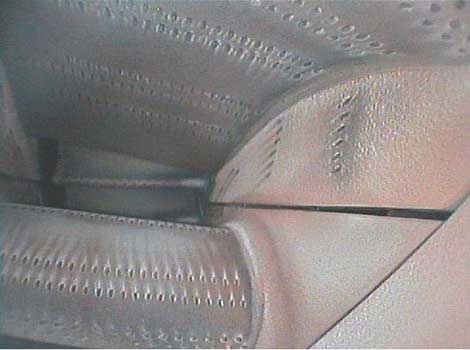

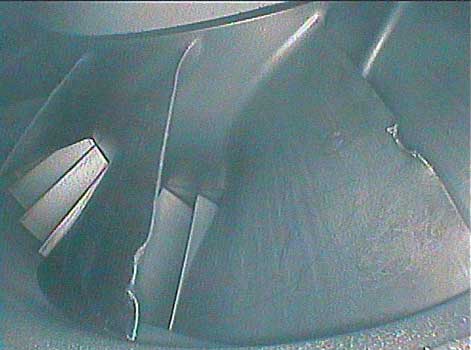

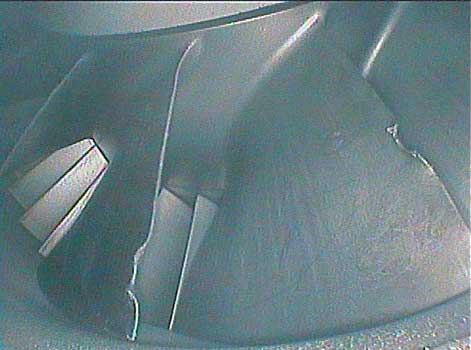

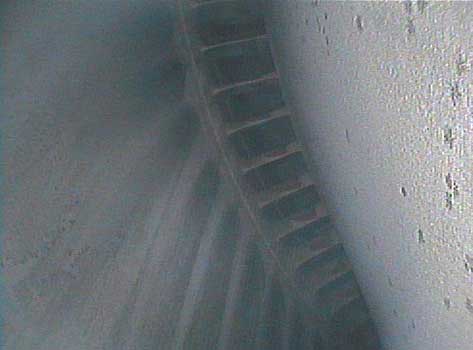

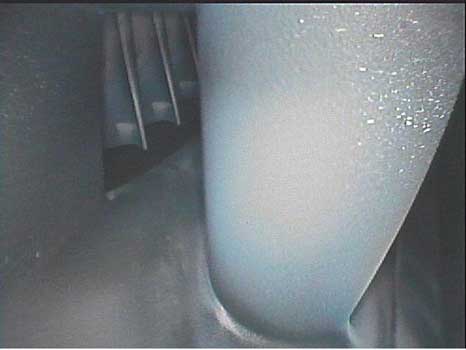

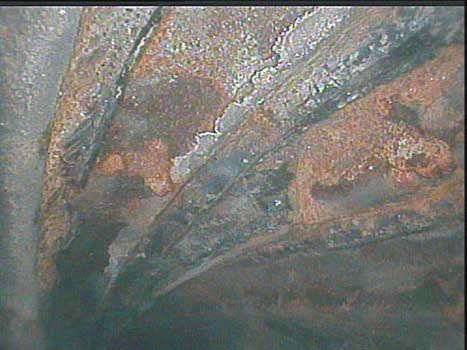

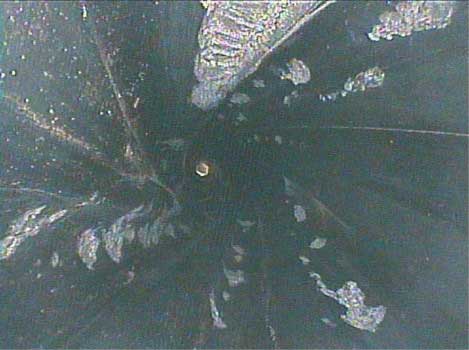

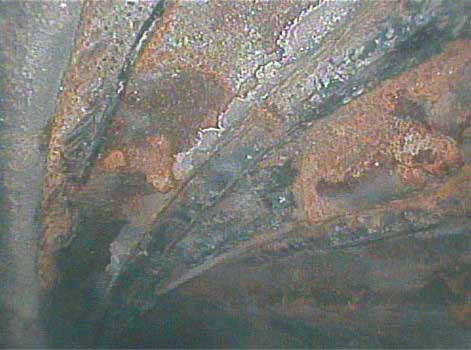

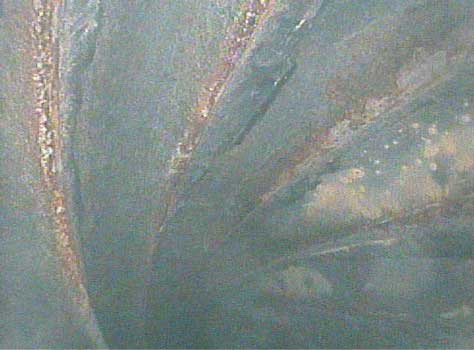

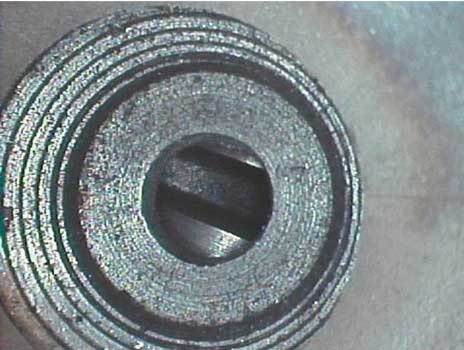

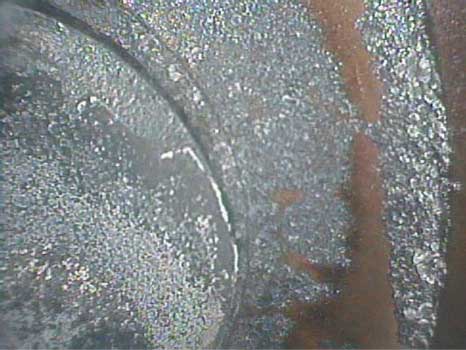

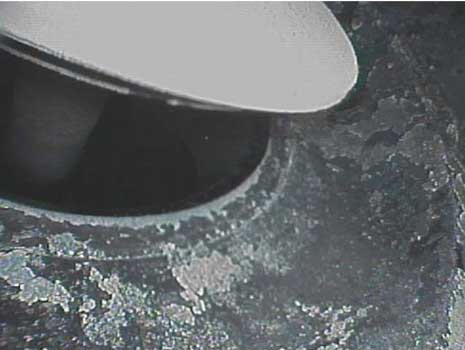

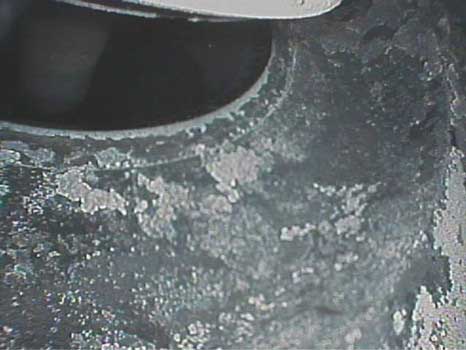

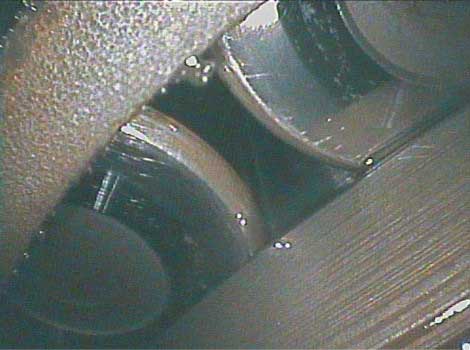

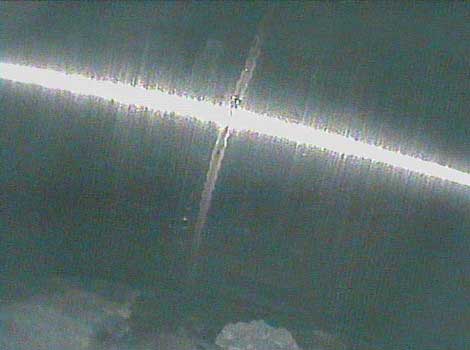

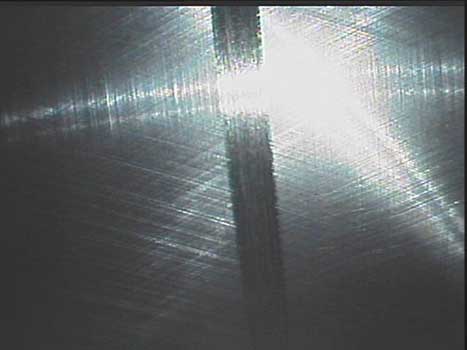

An aviation company located in the southern portion of the United States, has a mission to provide the safest and highest quality traditional aircraft operations, completions and maintenance. This company uses the 3.9 mm x 1.5 M VJ-Advance (VJ-ADV) articulating video borescope to inspect helicopter engines. The VJ-ADV allows mechanics to explore areas of the helicopter engine that are too small, too remote or out of reach through other means. When the borescope’s insertion tube is directed through an opening, it allows the lenses to view what needs to be checked. Disassembly of a piece of an aircraft is time consuming but the VJ-ADV borescope cuts out this step and diagnoses problems or determines the quality of a particular part in a way that promotes less work and less time. The VJ-ADV is battery operated, easily portable and the 360-degree articulation gives the ability to scan the entire area to see everything without taking it apart.