The term “borescope” has become a generic term used to describe three types of products/technologies that are used for remote visual inspection. These products are “borescopes”, “fiberscopes”, and “videoscopes”. There are actually key differences between these inspection cameras, but because the earliest RVI product was called a “borescope”, the name stuck even as new technologies were added to the industry. After this review, you will understand why the term “articulating borescope” is an oxymoron, but we still use it because that is the terminology the industry has adopted. In this review, we will use the strict definition of these products.

RVI has been around for about 80 years. The earliest RVI systems were simple tubes shaped like long, thin telescopes, with an eyepiece on the proximal (near) end and an angled mirror pointed toward an opening in the tube on the distal (far) end. Called “borescopes”, they were used to look inside bores (holes) in a machine, vat, tank or pipe. Think of a periscope on a submarine as a borescope looking through a “bore” in the surface of the ocean.

Shown here is a rigid borescope which will work very well for situations in which you have direct, straight-line access to your inspection target. Gunsmiths use them to inspect the inside of gun barrels. They are often the best option for very small bore, straight pipe inspection or small part inspection. The rigid borescope does not work well for viewing inside of items with irregular internal cavities such as motors or equipment.

Shown here is a rigid borescope which will work very well for situations in which you have direct, straight-line access to your inspection target. Gunsmiths use them to inspect the inside of gun barrels. They are often the best option for very small bore, straight pipe inspection or small part inspection. The rigid borescope does not work well for viewing inside of items with irregular internal cavities such as motors or equipment.

Fiberscopes arrived on the market about 35 years ago with the development of fiber optics, which are basically extremely thin strands of glass. Fiberscopes bundle together anywhere from 3,000 to perhaps 30,000 or more or these strands. A lens is attached to the distal end of this fiber optic bundle, and an eyepiece is attached to the proximal end. The image captured by the lens is carried through the bundle and shows up on the eyepiece. The user can put the eyepiece to his eye and see the image, or the eyepiece can be attached to a camera which displays the image on a monitor. In some systems, the outer ring of fibers in the bundle is used to transmit light onto the inspection target, while the inner fibers are used to carry the image back to the eyepiece. In these cases, the system must include a separate light source (usually halogen light) at the proximal end, and the light is transmitted down the outer circle of fibers to provide the illumination.

The main advantage of fiberscopes over borescopes is that fiberscopes are flexible and can therefore be used for inspections in which straight-line access is not available.

Fiberscope without articulation capability

The fiberscope shown here does not have articulation. Many fiberscopes do have articulation, which simply means that the distal two inches (approximately) of the scope can be pointed in any direction, usually by means of control knobs located at the proximal end. These control knobs are explained in more detail elsewhere in this document.

The fiberscope shown here does not have articulation. Many fiberscopes do have articulation, which simply means that the distal two inches (approximately) of the scope can be pointed in any direction, usually by means of control knobs located at the proximal end. These control knobs are explained in more detail elsewhere in this document.

Also, many of the very low cost fiberscopes, carried by auto parts stores, for example, use plastic fibers instead of glass fibers. The image quality for these scopes is quite poor.

Videoscopes are similar to fiberscopes in that that there are both articulating videoscopes and non-articulating videoscopes. The main technical difference between videoscopes and fiberscopes is that a videoscope has a micro video camera located at the distal end of the insertion tube that directly captures the inspection image and electronically carries the video signal down the insertion tube to a pcb/video processor and display, which are usually integrated into the unit.

A fiberscope may have a video display unit attached to it, but it will be an indirect display of the image, since what is actually being displayed is a picture of the fiber optic bundle that captured the image. This may at first seem like a small distinction, but it is a very important one. The VJ-Advance videoscope from RF System Lab, for example, has an image sensor with 307,000 pixel resolution. No fiber-based scope comes close to delivering this level of resolution. Additionally, fiber optic-based scopes are subject to “pixilation” or “broken pixels” or “black dots”. These terms refer to what happens when some of the fibers in a fiberscope break, which is inevitable given the flexible nature of the scope and all the bending that occurs during normal use. What you end up with are black dots in your image because those fibers are no longer carrying their part of the image back to the eyepiece or attached camera.

Today, we are in the middle of a long transition in RVI technology, moving from fiber optic-based scopes to direct video-based scopes. Many products on the market still use fiber optics and halogen light sources. Only recently has camera technology been miniaturized to the point where you can actually fit an entire camera and lens on the distal end of a small diameter insertion tube. Along with micro LED technology to provide illumination, this is the future of RVI.

At the extreme high end of the market there are a mix of true videoscopes as well as fiber-based scopes with video camera attachments. The videoscopes from these companies are great products, but they are very expensive.

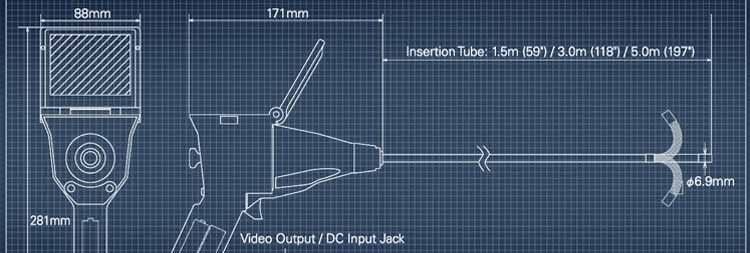

RF System Lab has been developing and refining micro digital cameras for over 12 years, with a focus on dental and medical camera applications. The VJ-Advance videoscope is the first RVI product that incorporates RF System Lab’s medical camera technology, transferring it over to the industrial inspection market. The camera and optics are medical-grade and very high quality, offering a great combination of features and price.

RF System Lab has been developing and refining micro digital cameras for over 12 years, with a focus on dental and medical camera applications. The VJ-Advance videoscope is the first RVI product that incorporates RF System Lab’s medical camera technology, transferring it over to the industrial inspection market. The camera and optics are medical-grade and very high quality, offering a great combination of features and price.

RF System Lab’s new VJ-ADV Borescope delivers the tremendous potential of true video-based RVI technology to a much wider range of customers. Call us now to learn more about our video borescope systems!